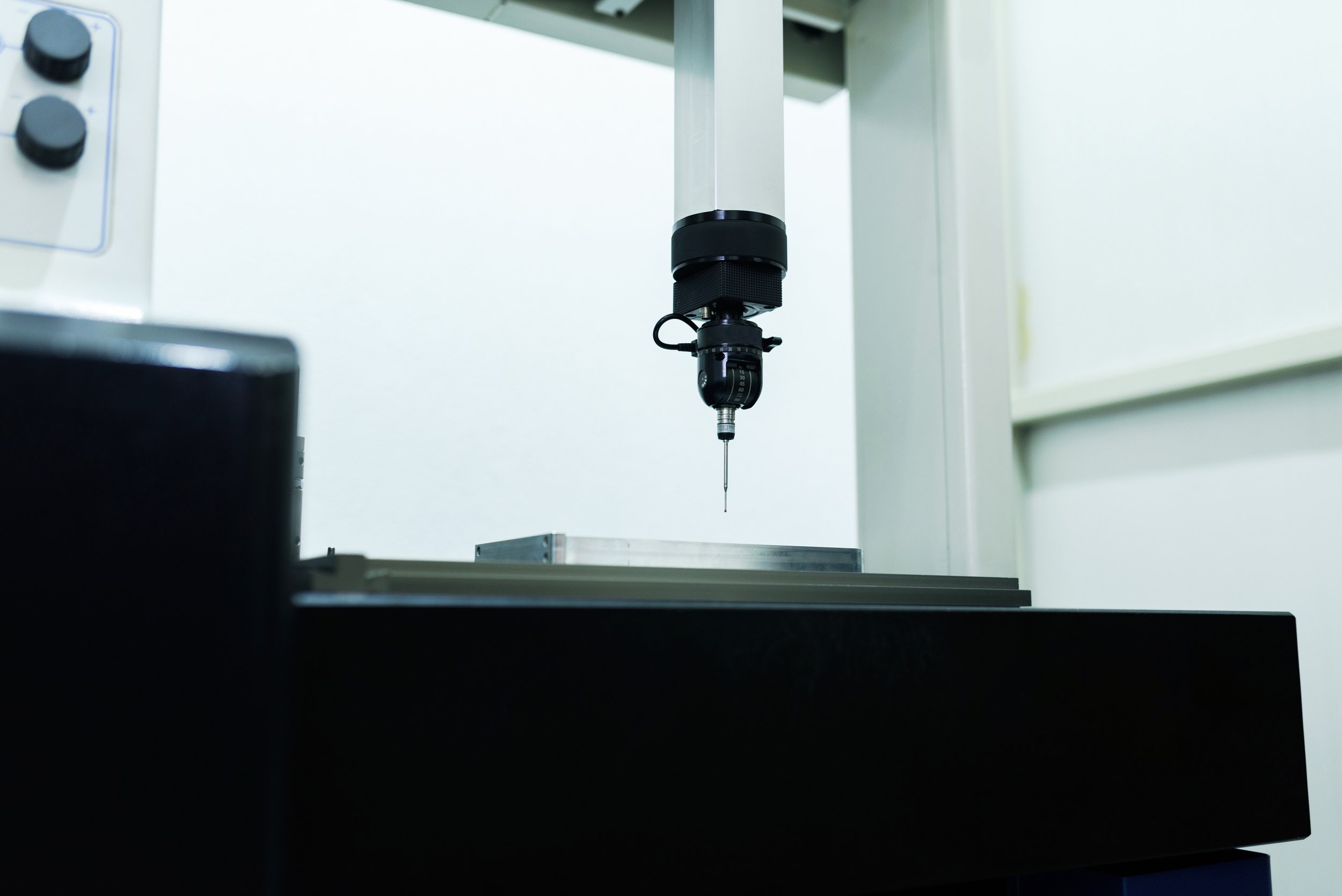

Quality Inspection

To ensure that all parts leaving the factory are of the highest quality, every one is inspected by our skilled team of metrologists. Components are measured to a resolution of 0.1µ to determine surface roughness and dimensional accuracy. We utilise two high-end CMMs (Coordinate Measuring Machines), a Hexagon RS6 Laser Scanner with a probe, a Baty R400 Profile Projector and a huge array of mechanical and digital measuring tools to guarantee quality.

Our working sizes:

CMM Big – 1200 x 1600 x 900mm (X,Y,Z) Resolution 0.1µ

CMM Small – 905 x 1600 x 605 (X,Y,Z) Resolution 0.1µ